Do you have a dream for your kitchen? It is more than likely that you do. Whether it is a compilation of contemporary, minimalistic kitchens on a Pinterest board, or a specified plan including exact colours and styles for your current or future kitchen, there is some inspiration within all of us to have a kitchen of our dreams, and we have some idea what this would look like.

However, kitchens are the most difficult room in a home to renovate as they require a lot of planning, research and precise calculation to ensure that everything will function and that the best result is achieved.

The most important element in a kitchen renovation is the cabinets. Cabinets are what first comes to mind when you hear ‘kitchen renovation’. These are the main feature of your kitchen, and will set the tone for how your kitchen functions, as well as set the stage for the design of the space. When you begin your research to decide who from, where, and how you will buy your cabinets, you will notice three available options: Stock Cabinets, Semi-Stock Cabinets, and Custom Cabinets.

What are the differences between these options, and why do they matter? How can you ensure that your cabinetry choice is the right one for your home, and will reap the most successful results?

OPTION #1

STOCK CABINETS

WHAT ARE THEY?

Stock cabinets are cabinet boxes that are pre-built by a manufacturer based on industry standard styles, measurements and finishes. They are mass-produced in a factory off-site and ready to ship as soon as they are ordered. Convenient, right?

Sure, the cost and the quick turn-around might sound exciting, but their build quality and customization options are where they fall short. These cabinets are modular units, and only are available in standard dimensions for base cabinets, upper/wall cabinets and tall/pantry cabinets.

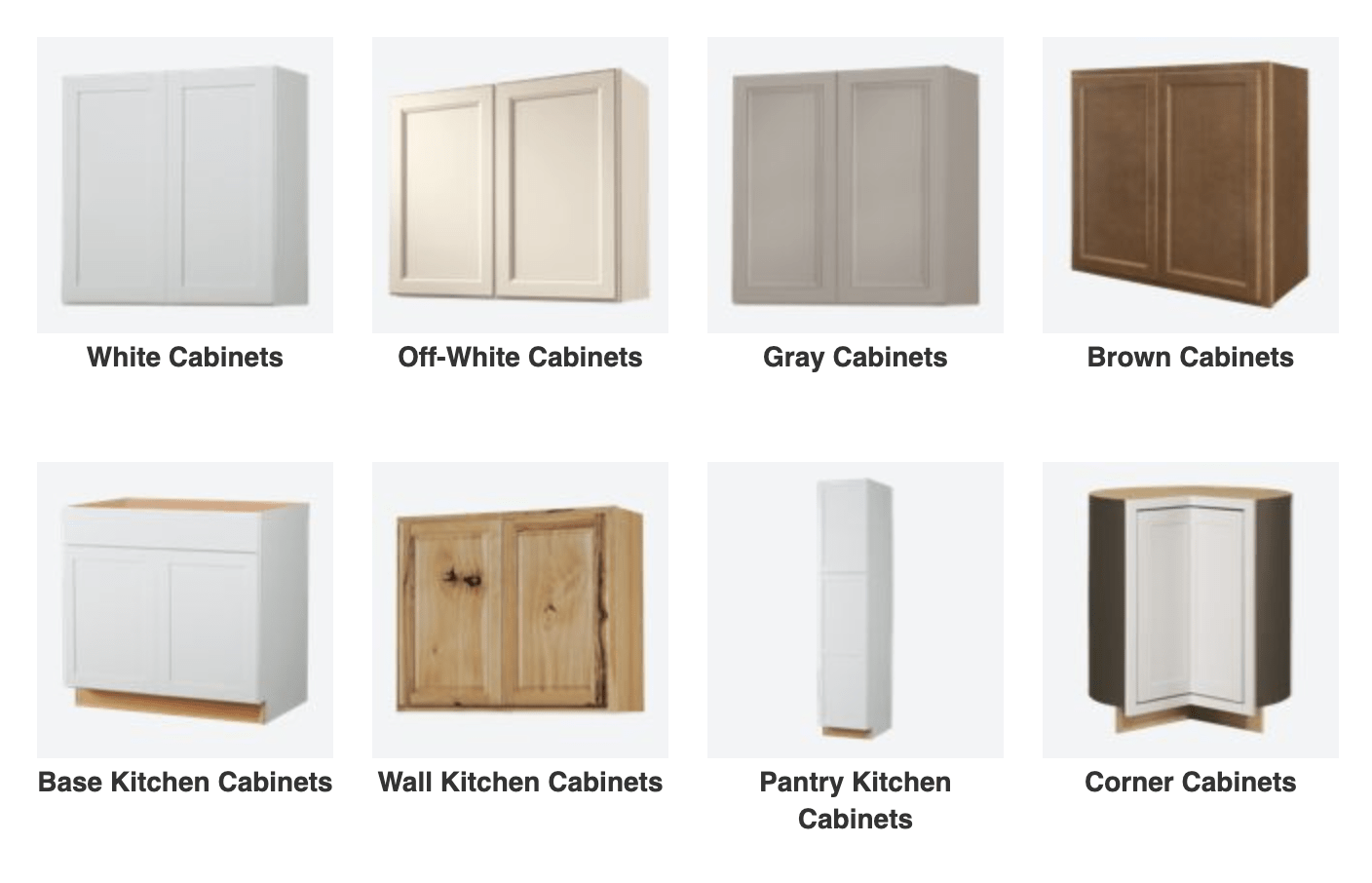

Example Stock Cabinet Catalogue

CUSTOMIZATION OPTIONS:

Common stock catalogue options are as follows:

Styles:

- Single Door Cabinets

- Double Door Cabinets

- Series of Drawers

- Combination of Drawers and Doors

Sizes:

Boxes

- Standard Width: Approximately 9″ – 40″ with 3 inch increments

- Standard Depth: 12″ for wall cabinets, 24″ for base cabinets

- Standard Height: 30″, 36″ or 42″ for upper cabinets, 84″, 90″, 96″ for tall/pantry cabinets

Drawers

- Commonly offered in 6″ and 12″ sizes

Finishes

- Commonly white, grey, natural wood, or stained maple or cherry

OPTION #2

SEMI-STOCK CABINETS

WHAT ARE THEY?

Semi-stock cabinets are similar to stock cabinets in the sense that they are built-off site to a set of industry standard sizes, styles and finishes. They are also mass produced and ready-to-order.

The only difference is their extra detailing options, with often customization options such as changing certain dimensions of cabinet drawers and their respective drawer fronts. However, input is limited as “customization” options are still pulled from a catalogue in the same manner as stock cabinets. Also, a higher price point coincides with this larger catalogue of choices.

STOCK/SEMI-STOCK CABINETS:

DISADVANTAGES

Aside from the benefits of stock cabinetry that are fast turn-around times and a lower price point, there are countless disadvantages that come with made-to-order cabinetry. Along with limited customization options with stock cabinets, the following additional disadvantages can cause disruptions to your kitchen renovation:

#1: Understanding Measurements

Every kitchen is different. Depending on the style of home, the floor-plan and ceiling height can change drastically. To order stock or semi-stock cabinets, the purchaser has to measure their kitchen dimensions and decide which cabinet fill fit in which location and use their own expertise to try to optimize the space with the options provided. Not only can this get complicated, but it also leaves a margin for error given abnormalities in ceiling height and incorrect measurement techniques. The measurements of your kitchen will never perfectly fit with the options for stock cabinets, leaving you with awkward gaps and a space that is overall under-utilized.

Empty Space caused by Stock Cabinets

#2: “Details” Not Included

Not only must the person measuring the kitchen ensure that the measurements are consistent and precise, but it is also important to account for space for crown-moulding or furring, floor-kick, end panels and filler strips. Given that these often aren’t included with stock cabinets, it is up to the purchaser to account for these items and ensure that the stock cabinets allow for the proper amount of room for a correct fit.

Stock Cabinets: No Kick, No Furring/Crown

#3: No Relationship With Cabinet Maker

Buying stock cabinets is a single-point interaction. You go in to the store, look at a catalogue, and choose the sizing, style and finish of your cabinets. The salesperson in charge of assisting you in making these choices has not seen what your current kitchen looks like, including the layout, the flooring, the colours utilized in surrounding rooms, the colour of your trim, and the general feeling of your home. Furthermore, you as the customer have not had a chance to visualize how the proposed finish and style would look in your space, rather you have to piece the cabinets together in your head and merely imagine how the space will look based on a colour swatch and a small door example. This lack of relationship between buyer and seller does not only impact the initial decisions, but also prevents any input that you as the customer may have during the process as the choices are finalized on purchase.

#4: Reduced Quality

Stock cabinets are most times less expensive than custom cabinets, although this is not always the case. However, these cost savings are often at the expense of quality. Stock cabinets typically use lower quality hardware, such as plastic side-mounted drawer slides, stapled drawers, and hinges that are not soft close. Stock cabinets often do not have solid cabinet tops, and have thin cabinet backs to save on material.

Stock Cabinet: No-Top. Reduces Quality and Durability

#5: Minimal Process Control

Stock cabinets are not designed, manufactured, or installed in-house. This means that the individuals or team that is in charge of the design of your kitchen are different from the individuals that were in-charge of your manufacturing, as well as a separate group of individuals installing your kitchen. This results in a lack of full understanding of your goal for your kitchen and opens the possibility of miscommunications during the process, or a delay in coordination of the final product. In addition to the complex initial process, if you need a replacement part or require service, those different groups of individuals will need to be coordinated once again, rather than a unified team completing these aspects in-house.

OPTION #3

CUSTOM CABINETS

WHAT ARE THEY?

Custom cabinetry is fully customized to your space and your design preferences. Your requests are discussed with a cabinet maker who controls the design, manufacturing and installation process in-house. You are not limited to a catalogue, rather the dream that you have for your cabinetry can become a reality. Some companies that advertise creating custom cabinets do not manufacture the cabinets themselves, but rather order them from a supplier to assemble and install themselves. This is not truly custom and it causes a greater risk of error as there is lost opportunity to directly express your wishes.

Custom Kitchen for a client in Toronto, ON. Colours: Grey Owl and Chelsea Grey

ADVANTAGES

1. FULL CUSTOMIZATION

The greatest advantage of custom cabinetry is full customization. Rather than attempting to place pre-built cabinets to fit in your space and scrambling to fill the gaps, our custom cabinetry is manufactured using CNC technology.

CNC machines are mechanical devices that use computer programming inputs to transform pieces of material to finished product down to the millimetre. The utilization of computer numerical control (CNC) allows for the product to be an exact result of your personal kitchen measurements in a productive and technical manner, eliminating possibility of error.

Our CNC machine cutting customized MDF cabinet doors.

2. FULL PROCESS CONTROL

Investing in custom cabinetry also means that you are able to work directly with a designer, who will take care of the technical elements such as measuring your space and planning the cabinet design. Rather than a display of a catalogue and minimal input as to which styles and sizes would work with your space, a designer will visit your home and observe all relevant aspects of your home including colour scheme and kitchen layout to determine which styles and sizing will be best for your space. As a client, you are able to visualize your kitchen come to life prior to manufacturing by viewing 3D drawings and suggesting further changes. If you need additional cabinets, replacement parts, or would like to implement custom cabinetry in another area of your home, there are no obstacles to tackle such as arranging the different parties involved in the manufacturing and installation and no worries as to whether the product is in stock or still offered in the catalogue.

Our Designers Brian Garrison and Jennifer Freiberg.

3. Enhanced Quality

Working directly with a cabinet maker who has control over the design and manufacturing of your cabinets, a high quality output is ensured. At Frank Bouwmans Cabinet Maker Inc, we utilize the highest-grade, locally-sourced materials and hardware to ensure durability and longevity.

1/2 Inch Plywood Drawers with Dovetail Joints

Undermounted Salice Soft-Close Drawer Slides and Front-Mounted Clips

Soft-Close Hinges

Now that we have reviewed your options in choosing cabinetry, the most important element of your kitchen renovation, are you sure that your dream kitchen can be achieved with stock cabinets?

Given that kitchen renovations are the most difficult room in your house to renovate, it is important that you reap the most successful results possible that will last the test of time and allow maximized functionality and aesthetics.

If you would like to hear more about how our millwork techniques achieve customized results that are on-time and on-budget, read our related design blog articles here:

Follow Along:

Recent Comments